The combination of rigidity and flexibility, the beauty of metal fiber materials

Published on:

2020-05-04

When a wire rod with the thickness of the little finger has undergone numerous cluster drawing, annealing, solid solution ... The length of the drawn metal fiber can go around the earth once.

Metal fibers are thinner than a hair, but still have the inherent performance advantages of high elasticity, high bending resistance, and high tensile strength of metal materials. At the same time, they can also have some special properties of non-metal fibers to meet wider application needs.

Compared with other organic or inorganic fibers, metal fibers have higher mechanical strength, high temperature resistance, corrosion resistance, and better electrical and thermal conductivity and sintering properties.

As a result, composite materials based on metal fibers have shown broad application prospects in the fields of electronics, chemical industry, machinery, military, textile, food, medicine and other industries.

1 Textiles

After metal fibers are processed into composite materials or yarns, they can be used in various textiles. The metal fiber fabric has the characteristics of anti-radiation, anti-static, high temperature resistance, and has both softness and elasticity.

Metal fiber textiles can be used in various applications such as high temperature resistance, anti-static, electromagnetic shielding, such as mold cloth for automotive glass production, electrostatic brushes for printers, anti-static work clothes, anti-electromagnetic shielding maternity clothes, etc.

2 filter

After the metal fibers are sintered, a high-performance filter medium, a metal fiber sintered felt, is formed. Its high porosity is suitable for fine filtration applications: increasing efficiency, saving operating costs, and reducing environmental pollution.

Compared with traditional filtration, metal fiber filter material has higher flow rate, strong dirt holding capacity, long online life, easy cleaning and processing. Therefore, it is widely used in polymer filtration, filtration of fuel, lubricating oil and hydraulic oil, as well as high temperature flue gas filtration and HEPA filtration, etc.

3 Conductive plastic

Metal fibers are the perfect filler material when added to plastic composites. It can protect electronic products from electrostatic discharge, prevent plastic parts from discharging and shield electromagnetic interference.

This technology simplifies the process of plastic molding. It can be molded in one shot, and high-quality products can be obtained without secondary processing. In addition, metal fibers can achieve high-efficiency EMI shielding and ESD protection functions with only a small amount of addition, which not only saves costs, but also provides a safe, healthy and environmentally friendly solution.

Relevant News

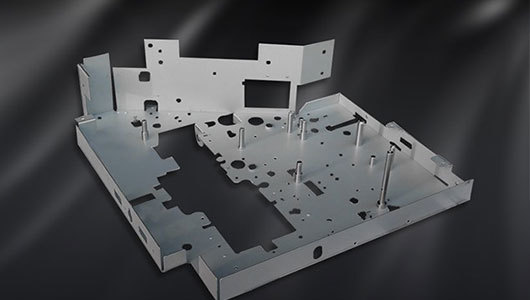

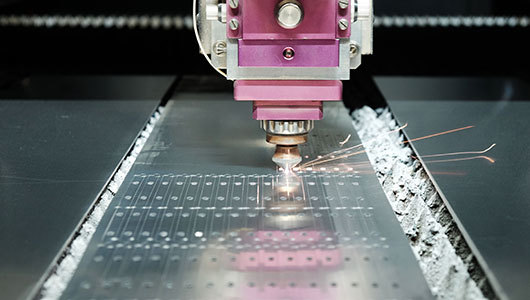

Sheet metal processing production process

2022-07-06