Let's share what problems should be paid attention to in sheet metal processing and bending?

Published on:

2022-06-06

Let's share what problems should be paid attention to in sheet metal processing and bending?

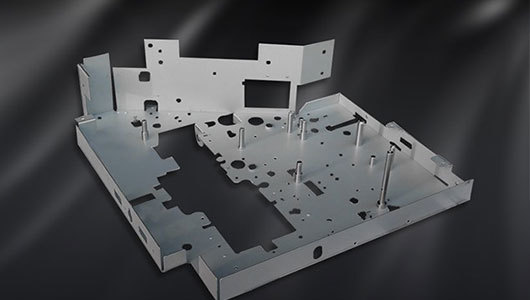

With the continuous development of the industry, we know a lot of processing technologies, and we are still using these processing technologies. This is sheet metal processing. What problems should be paid attention to in sheet metal processing and bending?

1. Before starting the machine, check whether the machine is dangerous;

2. When opening the equipment, do not reach out from the edge of the bending machine to adjust the rear gear, but adjust directly behind the equipment;

3. When processing parts, the human body should be outside the range of motion of the parts to avoid scratching the human body;

4. When processing large workpieces, the human body should stand on the side of the workpiece to operate, and at the same time, grasp the workpiece to avoid injury or damage;

5. In an emergency, shut down the machine immediately;

6. When operating close to the knife edge, both hands should lean on the appropriate position of the lower die to prevent fingers from accidentally digging into the knife edge;

7. When the sheet metal is bent, place the sheet metal to keep the hand balance of the machine tool;

8. The removed tool cannot be placed on the bending machine, nor can it be leaned on the bending machine to avoid slipping and hurting people.

Whether it is sheet metal processing, sheet metal, or handicrafts, there will be more or less material loss.

When a sheet metal processing company processes a workpiece, whether it is outsourced or processed by itself, there will be material loss, but the loss is forgivable within a reasonable range, and additional materials can be used:

1. It can be used to make small objects or products;

2. For the materials that cannot be used up, find a special company to recycle or sell them to suppliers who sell materials to offset part of the cost. These companies usually have specific methods to deal with these problems, and remake scrap iron into new coils. Recycle.

In order to avoid serious material loss in the later stage, accurate calculation can be carried out according to the area when designing the workpiece. Generally speaking, there will be a professional sheet metal processing design team, and accurate design, layout and cutting can avoid more material loss.

In general, when we use the machine for a long time in the future, we must protect the machine, because this can make the machine more durable, but what method can be used to make precision sheet metal processing more convenient?

Then we had to scrub him with a cloth to fix the loose parts, in addition to that, we also need to protect the machine tool equipment, like relatively simple places to prevent rust, or some places to prevent rust and dust, after surface treatment, exposed Part of the rust prevention is very important, then we need to check the whole system to see if it is working properly, in short, we need to do the above points to make precision sheet metal processing more and more convenient, if you want to know more For more details, you can contact us directly.

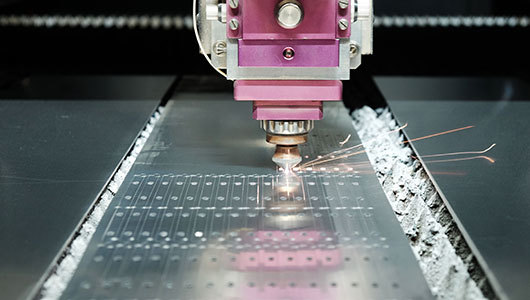

The key technology of CO2 laser cutting is the comprehensive induction technology of light, electricity and machine. In addition, the editor believes that some related parameters and equipment of the laser will directly affect the power and quality of laser cutting, especially for parts with high cutting accuracy or large thickness , you need to master the following key skills.

First of all, we should protect the damaged wires. If the damage is serious, we will directly replace the wires. Some brushes have problems with contact or are seriously damaged and need to be replaced. At the same time, the precision sheet metal processing adopts high-pressure airflow for finishing, and all internal dust is cleaned. Clean, check whether the card head and key are deformed.

Relevant News

Sheet metal processing production process

2022-07-06