What are the methods of sheet metal processing that will be shared below?

Published on:

2022-06-16

What are the methods of sheet metal processing that will be shared below?

Various technological processes can be completed through sheet metal processing. For example, in the processing of hardware products, this process can be used for processing and production. At the same time, the processing of various small parts can be completed, and the processing output can also be realized. In terms of cost control, the standard It is more reasonable, so many industries pay attention to it.

Nowadays, sheet metal processing has been widely used in various fields, so the sheet metal processing method has also been highly praised by everyone. In order to better ensure the quality of sheet metal processing, we will strictly follow the specifications, according to the appropriate processing method of sheet metal processing, You can adjust the use of the product. In addition, you must master the maintenance method of the sheet metal cabinet, which can prolong the service life of the sheet metal cabinet and save operating costs.

After the metal sheet is processed, it should be maintained according to appropriate methods. For example, the outer and inner layers of the sheet metal cabinet will rust, otherwise the service life of the sheet metal cabinet will be shortened. The sheet metal cabinet can be anti-fouling and cannot be exposed for a long time. If you find dust on the sheet metal chassis, you should clean it up immediately to maintain the beauty of the sheet metal chassis. This is a very important maintenance method.

In addition, the staff should not only pay attention to the steps and methods of sheet metal processing, but also rinse the sheet metal cabinet with tap water in time to clean the surface and prevent dirt and chemicals from being removed from the surface. During the entire cleaning process, soap will be added to apply this This kind of lotion can remove dirt more easily. After the above cleaning, you need to soak in cold water again to clean the water marks to keep the sheet metal cabinet dry.

Now the requirements for sheet metal processing are very high. During the entire processing of the sheet metal chassis, pay attention to whether the raw materials are damaged. If all surfaces of the sheet metal chassis are found to be damaged, please repair them immediately to prevent the damage from endangering the sheet metal chassis. use.

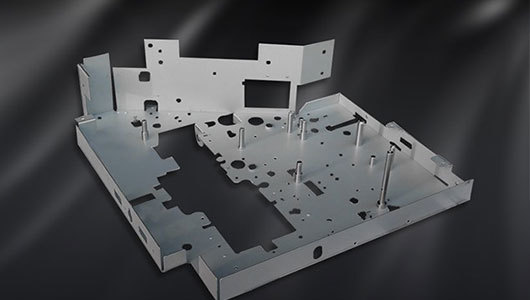

Sheet metal processing is called sheet metal processing. Specifically, chimneys, iron drums, oil tanks, oil tanks, ventilation ducts, elbows and small heads, circular areas, funnels, etc. are all made of sheet metal, and the main process is cutting , bending, forming, welding, riveting, sheet metal, etc., the parts are thin metal parts, that is, parts that can be processed by stamping, bending and stretching, generally defined as a constant part thickness during machining, corresponding to castings, forgings, Processed parts, etc.

Sheet metal processing is a key technology that sheet metal technicians need to master, and it is also an important process for sheet metal product forming. Sheet metal processing includes traditional cutting, blanking, bending, forming methods and process parameters, as well as various cold stamping die structures and Process parameters, working principles and operation methods of various equipment, stamping new technologies and new processes.

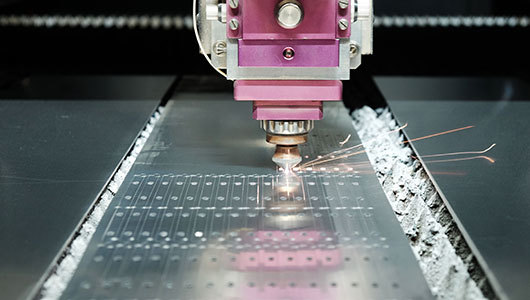

The sheet metal processing steps of the parts in the sheet metal processing workshop are: product initial test, product processing trial production, and product mass production. In the trial production stage of product processing, it is necessary to communicate with customers in time to obtain corresponding process evaluation before mass production, laser drilling Technology is a practical laser technology in laser material processing technology. Laser drilling in sheet metal workshops generally uses pulsed lasers, which have higher energy density and shorter time. It can process 1m holes, especially suitable for processing thin materials with a certain angle. It is also suitable for machining deep small holes and small holes in high-strength, high-hardness or brittle soft material parts.

Okay, I will stop here first, thank you for watching.

Relevant News

Sheet metal processing production process

2022-07-06