What are the precautions for sheet metal processing?

Published on:

2022-06-27

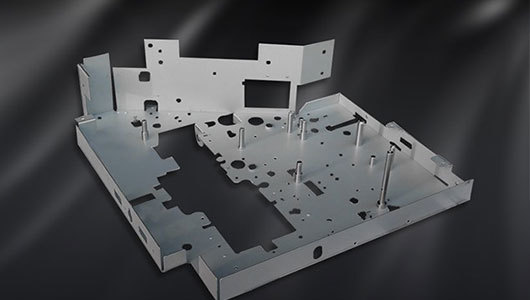

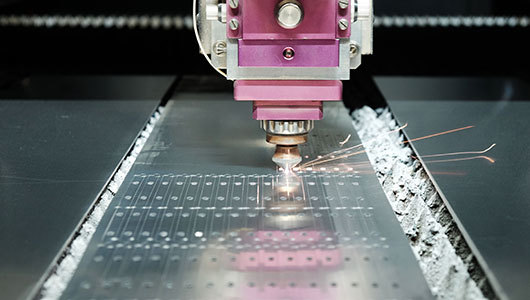

The sheet metal processing industry has many work requirements for operation, including a lot of work, such as blanking, bending and forming processes and materials. During the operation, personnel must pay attention to whether the parameters in the process are accurate and whether they meet the requirements. The standard requirements and application methods also attach great importance to the processing quality of materials in the workplace, so the application of technical skills and knowledge should also be paid attention to in the process of such processing operations, so as to meet the needs of industry development.

When processing materials for sheet metal processing, attention should be paid to reducing energy consumption as much as possible. For a task, reducing the input of materials does not have much effect on cost recovery, so for a large amount of processing capacity for a long time , if the main purpose of shortening investment and consumption can be reduced, more expenses can be reduced for manufacturers and more economic benefits can be brought to manufacturers.

In the process of sheet metal processing, in order to achieve the purpose of reducing investment, it is necessary for the staff to strictly abide by the production specifications to complete the work process. Before each processing, the application for materials needs to be reviewed first, and no processing is allowed without approval. Many wastes generated in the processing industry are caused by uncertain materials before processing. Therefore, workers must clear the types of materials before processing, and check the specifications of materials, and make preparations to avoid mistakes in the processing process. , It can also reduce the scrap of parts, and the staff should pay attention to these problems in the process of sheet metal processing.

1. To avoid breaking and cutting, open baffles should be installed at appropriate locations.

2. When polishing the surface of the workpiece with gauze, please move the tool to a safe position, and do not touch the surface of the workpiece with hands and clothes. When grinding the inner hole, do not use your fingers to hold the gauze, but use a wooden stick, and the speed should not be too fast.

3. Do not place objects, fixtures or workpieces on the bed and spindle drive. Think on the job. Stop fatigue operation, chat operation, multi-person operation, drinking operation, smoking operation.

4. Adhere to the orderliness of machine tools, materials and workmanship, and do a good job of changing shifts. When cleaning up the work area after work, turn off the power and keep all knife handles in a safe place.

5. When turning irregular-shaped workpieces, it should be equipped with a balance block, and then cut after testing the balance.

6. The tool holder should be reliable, the extension of the tool head should not exceed 1.5 times the height of the tool body, the shape and size of the gasket under the knife should be consistent with the shape and size of the tool body, and the gasket should be as small and flat as possible.

7. Unless the lathe is equipped with a measuring tool that can automatically measure during operation, it should be parked and moved to a safe position before measuring the workpiece.

8. When cutting, strip chips and long spiral chips should be eliminated in time, and hooks should be used to stop pulling by hand.

9. Before going to work, wear work clothes, tie cuffs, and wear protective glasses. Women should wear a work cap, with long hair in the cap, and stop wearing gloves.

10. The loading and unloading of the chuck on the spindle of the lathe needs to be carried out after the machine is stopped. The strength of the motor cannot be used to remove the chuck.

11. Use protective covers for the protruding parts of workpiece chucks, dials, and heart clips to avoid getting stuck on body parts such as clothes. If there is no protective cover, a certain interval should be adhered to during operation.

12. When using the top to clamp the workpiece, pay attention that the center should be exactly the same as the center of the center hole of the spindle. A damaged or skewed top should not be used. Before using the top, the center hole should be wiped clean, and the top of the tailstock should be upward.

13. When turning slender workpieces, in order to ensure operation safety and processing quality, a heel tool rest or a center tool rest should be used. For processing parts beyond the sheet metal processing range, mobile protective covers and safety signs should be set up.

Relevant News

Sheet metal processing production process

2022-07-06