Sheet metal processing production process

Published on:

2022-07-06

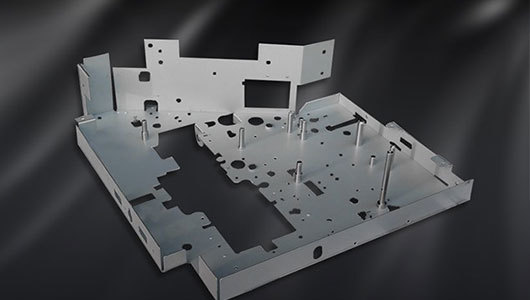

Now more and more sheet metal parts are applied to all aspects of our life. So what is the sheet metal processing production process? How do we apply it in our work? Generally speaking, sheet metal processing manufacturers usually follow the following steps to produce after receiving the official production drawings from customers.

1. Check the drawings

Why do sheet metal processing manufacturers usually re-examine the drawings in the first step? This is because many customers' engineers have not been exposed to the production process of sheet metal parts, and may not be proficient in the production process of sheet metal processing, so they often draw Drawings can have problems with details. Sheet metal processing manufacturers are very professional and proficient in these aspects, so sheet metal parts manufacturers will first check the drawings and confirm the finished product size and related requirements with customers. After clarifying the customer's needs, enter the preparation of the production process.

2. Determine the plate type and delivery date

This is mainly to confirm the material according to the customer's drawing requirements, and confirm the order quantity of the plate according to the order quantity. Whether the corresponding board is in stock at the factory or not, we need to inform the customer in time. Because this will directly affect the delivery time of the goods, especially for customers with urgent delivery time, if the delivery time is not communicated well in advance, they will be very passive in the later stage, and may even lead to breach of contract due to their own reasons. This has a bad effect on the reputation and reputation of the factory. Therefore, determining the plate type and delivery time is the first step to be done.

3. Sheet metal processing technology and production process

This is the key to the production of sheet metal parts. Generally speaking, the production process of sheet metal parts is as follows:

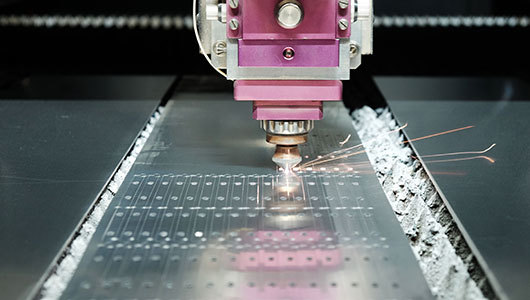

(1) The calculation of the expansion length is an important content. When calculating the expansion length, the expansion coefficients of different materials should be considered comprehensively. Generally speaking, for the expansion coefficient of common materials, each factory has experience, so we can apply. If it is laser cutting, we usually leave the allowance, if it is under the shearing machine, we need to reserve the machining allowance, and we need to determine the appropriate discharge method, because it directly affects the utilization rate of materials, well The discharge method needs to be as complete as possible under the premise of satisfying the processing technology of the parts.

(2) Bending, we use a bending machine in this step. According to the requirements of the drawings, we can choose a suitable bending die. If general bending dies cannot meet our requirements, we may need to make special bending dies.

(3) Mechanical processing. The main purpose of mechanical processing is that the two processes of cutting and bending cannot produce processing characteristics. Common ones are tapping and rivets. We can only complete these processes after bending. This is because If these processes are performed before bending, there may be deformation during bending, etc.

(4) Surface treatment, which is a set of processes before delivery. It is mainly for surface treatment of parts according to the requirements of customer drawings. Common surface treatments include wire drawing, painting, oxidation, etc.

(5) Packing for delivery, after the finished parts are completed, we will measure and inspect all parts. Here is mainly the inspection of appearance quality. There are no paint defects, no surface quality problems, etc. Dimensional measurement is also inspection and inspection. Generally speaking, the previous process is enough to ensure the accuracy of the finished product size, and the size control is carried out in the process. If the size problem is found before delivery, it is an unforgivable mistake for the sheet metal manufacturer, and the loss may be borne by the sheet metal parts manufacturer.

Relevant News

Sheet metal processing production process

2022-07-06