Let me share with you the application fields of sheet metal processing industry

Published on:

2022-05-23

Let me share with you the application fields of sheet metal processing industry

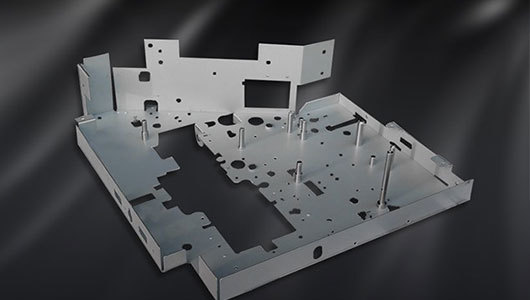

The editor tells you that sheet metal processing is actually the processing of metal products. More importantly, it is necessary to transform sheet metal to achieve its use in many different places. The processing methods include stamping, cutting and cutting to change the characteristics and shape of the metal. , The application of this technology not only brings great convenience to people's lives, but also promotes the development of my country's machinery industry. For the sheet metal processing industry, it can be applied to many aspects of understanding.

In fact, many things around us are realized through sheet metal processing. For example, every house needs stainless steel doors and windows, as well as electrical boxes and various control boxes, which require sheet metal processing. In addition, the development trend of sheet metal technology is large-scale such as the automotive industry, shipbuilding industry and various large processing plants.

It is suitable for the sheet metal processing industry. With the development of the economy and the continuous progress of the machinery industry, its development prospects are bright, and their demand is also growing. At present, the sheet metal processing industry needs to improve the technical level and innovation ability, and strive to introduce advanced production equipment to expand the production scale.

In order to achieve standardized and institutionalized operation, the sheet metal processing industry has a strict development plan, formulates a practical development plan, and strives to build its own sheet metal brand, and do not rely too much on foreign brands, which is very unfavorable to its own development. If you want to develop your own brand, you must continue to display and achieve extensive development.

All kinds of sheet metal processing cabinets are sandwich panel split solutions, ideal for roofers, house builders, factory builders, container carpenters, experts in cold protection, heat insulation, sound insulation, generally speaking, after sheet metal processing, the steel The functions and characteristics of the structural surface are processed into parts of various sheet metal processing equipment to avoid chemical corrosion and cause thinning of pipes, thereby improving the utilization rate of steel. A small factory added an acid solution to the paint to completely decompose the different dissolved water sources The process can improve the oxidation movement of the steel, the use of clean auxiliary steel can effectively improve the oxidation stability, the acid solution treatment can improve the smoothness and service performance of the product, and has sufficient stability and friction properties, therefore, different chemical solutions are adjusted. The durability and density of secondary steel technology can be improved.

After the sheet metal cabinet is processed, it needs to be maintained in the correct way. For example, the outer and inner layers of the metal cabinet may rust, otherwise the service life of the metal cabinet will be affected. Exposure, if there is dust on the surface of the metal cabinet, it should be cleaned in time to maintain the beautiful state of the metal cabinet. These are maintenance methods that cannot be ignored.

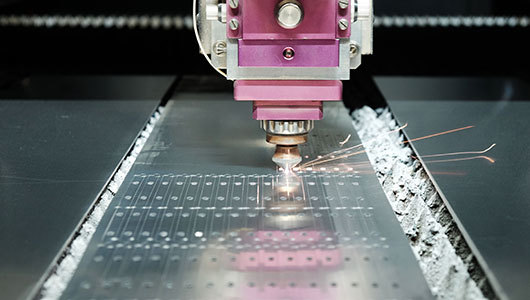

The important forming process of sheet metal products is also the key technology that sheet metal technicians should master. The traditional sheet metal stamping process includes material separation, cutting, bending, forming, the structure and process parameters of various cold stamping dies, various equipment and The working principle and operation method of stamping process, new technology.

The above is the content of the editor's explanation, thank you for watching.

Relevant News

Sheet metal processing production process

2022-07-06