What are the benefits of sheet metal processing?

Published on:

2022-07-18

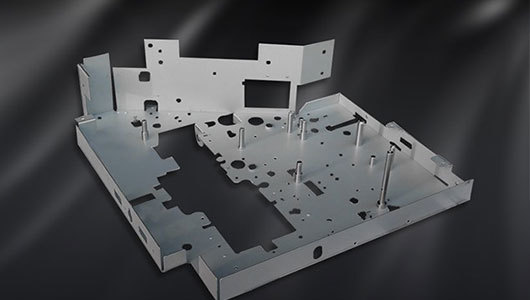

With the continuous improvement of the national technical level and the quality of life, as people's demand and quality requirements for sheet metal processing are also getting higher and higher, so here you need to know that its mechanical engineers in the processing plant need to master sheet metal parts Only in this way can we meet the requirements of customer products such as function and appearance, and can be loved and pursued by people.

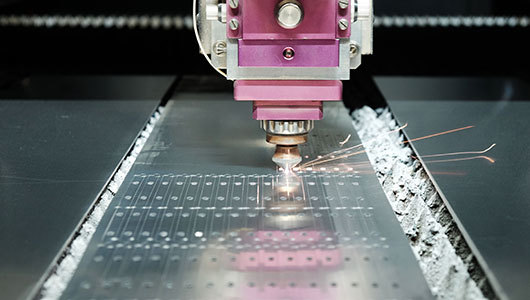

The significant advantage of this technology in sheet metal processing is that the cutting speed is fast and is not limited by the number of processing. However, it is more suitable for the processing of special-shaped workpieces during processing, because it does not waste time to replace, thus effectively improving the processing speed; therefore, to a certain extent, its processing speed and large positioning speed will be significantly faster than wire cutting. In addition, today's advantages are manifested elsewhere. For example, laser cutting in sheet metal processing is non-contact cutting, and heating has little effect on the cutting edge, which can avoid the adverse effects of thermal deformation of the workpiece. In addition, it completely avoids edge collapse formed during material punching and shearing. Weld seam cutting generally does not require secondary processing, which improves work efficiency to a certain extent; not only that, the cutting head will not contact the surface of the material, thus effectively ensuring that the workpiece will not be scratched. Storing lubricants in the name of product workpieces is certainly difficult. A key aspect of fine stamping is punching. For example, there are many small holes in small machinery and small instruments that need to be punched. Therefore, the scientific research of small hole punching is the key issue of fine punching. In the process, we can see that the scientific research on punching mainly focuses on.

For example, how to reduce the size of the punch; there is also a common problem of how to improve the compressive strength and bending stiffness of the unimportant die base (besides the materials and processing methods that spread to production and manufacturing, of course, we also see A common thing is to improve the guidance and maintenance of unimportant formwork). As long as scientific research is required in punching, there are still many problems, but many promising results have been achieved. Of course, sheet metal processing has many advantages. It can quickly process aluminum alloy plates and cemented carbides, no matter how hard they are, they can be cut without deformation. Its processing flexibility is very good. In this case, it can not only handle any kind of graphics, but also cut pipes and other odd materials. For most non-metallic materials, it can also be cut quickly, so it is not limited by any material properties. In addition, there are some important aspects in the future, namely the high production efficiency of sheet metal processing. In particular, it has high precision and solid quality. Material utilization is high. Overall, its practical operation is simple, and it is especially suitable for mass production and integration. For the mold shell industry chain, due to the continuous development of the miniaturization and precision requirements of the punching machine, only in this way can higher requirements for the mold shell method be clearly put forward. The reason is that micromachines are harder to shape than conventional machines. The reason is that the smaller the machine, the larger the size and volume.

After the introduction of the above content, we have also learned about the benefits of sheet metal processing. Other knowledge points will continue to be updated in the next issue. If you have time, come and watch it. I believe it can help you.

Relevant News

Sheet metal processing production process

2022-07-06