The meaning and steps of painting the surface of sheet metal processing

Published on:

2021-11-15

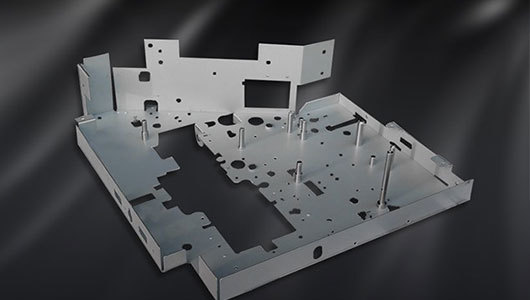

The coating process of the sheet metal surface is used for sheet metal processing. It is of great significance, and the surface coating has a protective effect on the sheet metal. Sheet metal cabinets, equipment enclosures, etc. are exposed to the air. And it will not be oxidized under the protection of the paint layer. So they won't rust and are waterproof and rustproof.

There are generally four steps in the painting process. Treat the base layer first, then do a primer coat. Add another coat of intermediate paint. Finally do the topping. Below I will describe the features of each step.

1. Primary treatment. The product foundation of sheet metal processing needs to be derusted first, such as sandblasting and phosphating.

2. Primer. Sheet metal fabrication uses an epoxy zinc-rich primer. The main purpose of this primer is to protect the steel structure and steel from rusting. The coating film has good physical and chemical properties, convenient construction and good matching performance. . Main components: epoxy resin, epoxy curing agent, zinc powder, anti-rust pigments, additives, organic solvents, etc.

3. Intermediate paint. Sheet metal processing products use epoxy micaceous iron oxide intermediates. Used in conjunction with epoxy zinc-rich primers as a transition layer for long-lasting anti-corrosion coatings. Its function is to enhance the sealing and anti-corrosion properties of composite coatings, and can also be used as anti-corrosion and anti-rust primers. The film is tough, with good adhesion and sealing properties. Good compatibility with front and rear coatings. . Its components are: epoxy resin and curing agent, iron oxide mother, anti-rust pigment, etc.

4. Surface layer. There are many kinds of spray paints that can be used for the topcoat, such as epoxy asphalt topcoat, chlorinated rubber topcoat, acrylic polyurethane topcoat, fluorocarbon topcoat, etc.

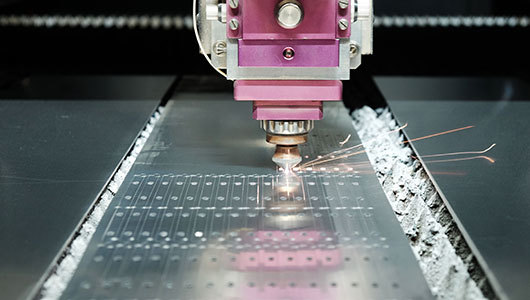

Although the current sheet metal is not accurate, sheet metal processing has brought great convenience to our lives. . For example, the cabinets commonly used on the Internet are all sheet metal products, which can be seen everywhere in our sheet metal processing products. . Since the development of the sheet metal industry, with the upgrading of technology, the four processes have also changed. With the addition of laser technology, the sheet metal processing process has become more complete.

Four important steps in sheet metal processing are cutting, punching/cutting, folding and welding.

1. Shearing machine: refers to a shearing machine that cuts steel plates into squares.

2. Punching/cutting: Punching refers to punching with a punch. Cut refers to the corner cutting of the punch die.

3. Folding: that is, the bending machine is bent into the required shape.

4. Welding: Sheet metal parts constitute the finished product and need to be welded by electric welding.

The main processes of the new four sheet metal processing are: excitation, punching, folding, welding, mainly the replacement of cutting equipment.

1. Laser cutting is the main equipment for blanking in sheet metal processing. Because of its fast processing speed, high precision, short cycle (without mold opening), and the ability to process various shapes, it is the main processing method for sheet metal blanking.

Sheet metal processing

2. The parts that need to be punched: sheet metal processing cannot only be flat. Need to punch a convex hull, sprout, punch blinds, bridge, snap, etc. All need to be cleaned and disposed of. With the development trend of mechanical equipment to the direction of CNC and automation, CNC punching machines are now used. Dozens of molds can be installed, programmed according to requirements, with high efficiency, and can also assist laser cutting machine blanking.

3. Folding: Compared with the old craft - folding. Only CNC bending machines, bending centers (manipulator-assisted bending), CNC bending machines and other equipment are added.

4. Welding: Compared with the old process - welding. Only argon arc welding, carbon dioxide gas shielded welding, welding robots and other equipment have been added.

Relevant News

Sheet metal processing production process

2022-07-06