What is the process of hardware processing?

Published on:

2022-01-07

What is the process of hardware processing? Let's analyze it together.

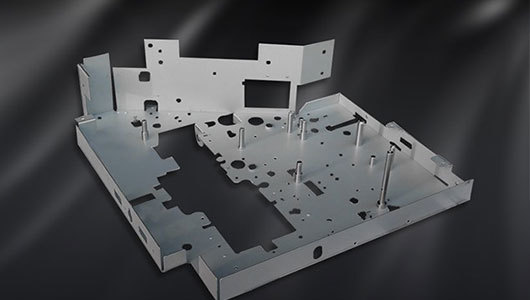

The hardware processing process is to open materials according to production requirements. Once opened, it can be punched like small parts, gong, CNC machining, which has many aspects in the production of eyeglass parts, auto parts. Manufactured container: It is welded after material stamping, sanded, sprayed, and shipped after assembling the parts. Hardware processing accessories require a lot of polished surface treatment, electroplating or spraying. Then, solder or screw assembly and packaging and shipping.

What are the operating steps of hardware processing? Let's analyze it together.

First, all employees will check whether their clothing meets the job requirements before entering the workplace. Do not wear slippers, high-heeled shoes and clothing that affects safety, and people with long hair should wear hard hats. When working, you should maintain a correct posture and handle things with full spirit. If you find that you are not feeling well, you should leave your job immediately and report to the leader. It is necessary to concentrate on the operation, and it is strictly forbidden to chat and cooperate with each other. The operator does not operate in a state of impatience and fatigue, so as to prevent accidents and ensure the safety of operation.

Second, before the machine is running, make sure that the moving parts are attached with lubricating oil, then check whether the clutch and brake are normal, and idle the machine for 1-3 minutes. It is strictly forbidden to run the machine when it breaks down.

Third, when replacing the mold, you need to turn off the power first, and then install and debug the mold after the stamping motion department stops working. After the installation and adjustment is completed, move the flywheel twice by hand to check whether the upper and lower molds are symmetrical and reasonable, whether the screws are firm, and whether the edge ring is in a reasonable position.

Fourth, other people have to leave the machine work area and take away the sundries on the workbench before starting the machine.

5. After the machine is started, one person can carry the materials and the machine, and the other person can't press the electric pole or the foot pedal switch board, can't put his hand into the machine work area or touch the moving part of the machine with his hand. When the machine is working, it is forbidden to reach out to the working area of the slider, and it is strictly forbidden to grasp the workpiece by hand. When taking and positioning the workpiece within the mold, it is necessary to use standard-compliant tools. If you find that the machine makes an abnormal sound or the machine malfunctions, you should immediately turn off the power switch for inspection.

6. When getting off work, turn off the idle power supply, sort out the finished products, sapwood, sundries, etc. of the work post to ensure a clean and safe working environment.

The above operating procedures need to be consciously abided by, do not violate the regulations, or cause a malfunction, and cooperate with the maintenance personnel in the maintenance. Once an accident occurs, the power supply should be cut off immediately and wait for the on-site report to the factory department for processing. All consequences caused by violation of the operating regulations shall be borne by the parties concerned.

Relevant News

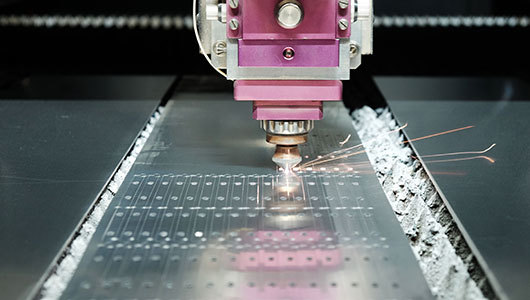

Sheet metal processing production process

2022-07-06