Precautions for logistics storage shelves

Published on:

2022-05-09

What are the important points to pay attention to when choosing logistics storage shelves?

(1) The structure of the logistics warehouse rack plant (available height | beam and column position | floor situation | fire facilities)

Optional racks for storage equipment should consider the effective height under the beam to determine the rack height. . The position of the beam and column will affect the configuration of the lathe. It is related to the strength of the floor, the flatness of the floor, the design and installation of the shelf. In addition, the location of fire protection and lighting should also be considered.

The shape and size of the object are directly related to the selection of shelf specifications, and the weight of the object directly affects the strength of the shelf selection. Storage unit What unit is it stored in? There are different types of shelving options for pallets (pallets), storage cages or items. In addition, estimating the total amount of storage needs to take into account the company's growth needs in the next two years. . These data can be obtained through storage system analysis, or professional advice can be sought before design.

(3) Accessibility of logistics storage shelves

Typical access and storage densities are relative. That is, in order to obtain high storage density, the accessibility of relative sacrificial items needs to be sacrificed. Although some types of shelves have high storage density, they are more complex than storage space management and often cannot be controlled by FIFO. Of course, the better is the three-dimensional automated warehouse, which can be developed upwards, has high accessibility, and has high storage density, but the investment cost is relatively high. So which storage device to choose, . It can be said that it is a compromise of various factors, and it is a strategic application. A comparison of the accessibility and storage density of each storage device can be inquired over the phone.

(4) Loading and unloading equipment (counterweight|horizontal tower|channel width|lifting height|lifting weight|rotation radius)

Access to the storage device is performed as a bearer device. Therefore, the selection of storage equipment should also consider handling equipment. The stacker is a typical handling equipment, and the width of the shelf channel directly affects the selection of the stacker (counterweight or narrow alley).

(5) Number of detections

Some styles of racks have better storage density, but the storage capacity is not high, which is suitable for low-frequency work. High out-of-stock quantities are important data and a consideration in shelf format selection.

Relevant News

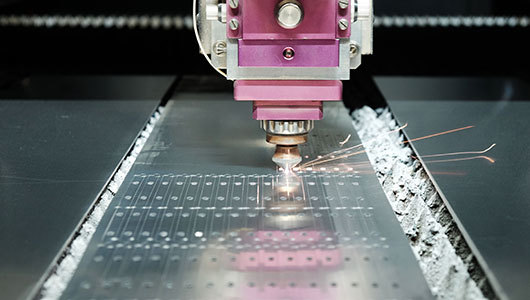

Sheet metal processing production process

2022-07-06