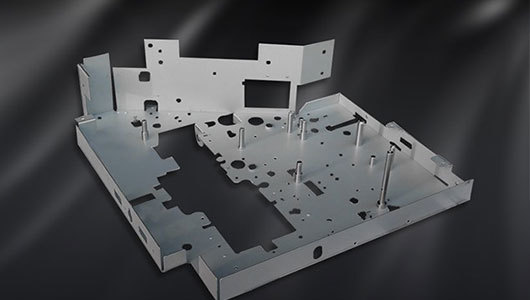

PC-computer control cabinet

The front lower cabinet door is equipped with a luxury crank lock, and the inspection door is equipped with a standard flat lock, which reasonably reflects the humanization of the cabinet design.

key word:

key word:

钣金加工 | 物流仓储货架 | 五金加工冲压件类 | 零售货架

Classification:

Product Details

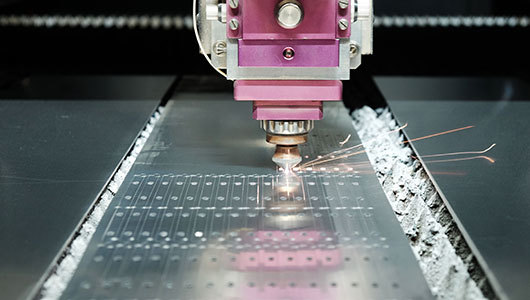

Sheet metal processing is mainly to complete the production of products by cutting, forming, correcting and assembling various metal materials. Therefore, you must have certain knowledge about the quantities, properties and uses of common metal materials in order to use these materials reasonably and master the correct sheet metal processing techniques.

Sheet metal processing and cutting

The cutting method is to use a disc shearing blade to cut the sheet in the opposite rolling direction. According to the disc equipment, it can be divided into linear equipment, oblique linear equipment and oblique equipment. Straight equipment is suitable for cutting sheet metal into strips or cutting square blanks into circular blanks in sheet metal processing. The oblique straight equipment is suitable for cutting circular blanks or circular inner holes, and the oblique equipment is suitable for cutting arbitrary curves. blank.

1. Straight equipment to cut paper. When using the straight line equipment to cut the plate, please align the straight line center line of the upper and lower hob first, the gap between the upper and lower cutting blades is usually 0.05-0.5mm, or adjust the upper and lower hob a little. Sheet metal processing The stacking conditions make the stacking height h generally only 0.2-0.3 times the thickness of the shear plate.

2. Sheet metal processing cutting board with tilting equipment. Beveling equipment is widely used for cutting curved boards. Before cutting the paper, the upper and lower reels are tilted devices, and the angle between the upper and lower reels is set to 25 degrees. Then adjust the speed and gap of the egg cutter according to the thickness of the slices.

3. The cutting dimensional accuracy of beveled sheet metal processing equipment. When a generalized disc rolling and shearing curve is chosen, the radius of curvature of the blank has a certain limit, and its small radius of curvature is related to the diameter of the cutting blade and the thickness of the half-body material, and when in the disc rolling For straight bars, the small width error is also limited.

Process characteristics and performance of PC computer control cabinet:

The main body of RAL7035 and the decorative strip of RAL5018 show the high-end quality of the cabinet

The surveillance area is equipped with non-reflective safety glass to ensure safety and reliability

The frame of the ten-fold profile ensures the flexibility and convenience of internal installation

The front and lower cabinet doors are equipped with luxury crank locks, and the inspection doors are equipped with standard flat locks, which reasonably reflect the humanization of cabinet design.

The keyboard and mouse system with humanized design highlights the quality of the cabinet

Material: cold rolled steel plate, aluminum alloy profile

Surface treatment: cabinet phosphating primer treatment, powder coating on the outside, color RAL7035, decorative strip RAL5018 two textures, the laminate is the same color as the cabinet

Protection class: IP54 (according to GB4205-1993)

Standard configuration: cabinet, rear door panel, front upper glass door, front lower steel door, keyboard drawer, sealing strip, shelf, door lock, casters (optional)

Steel plate thickness:

Decorative strip: aluminum alloy

Door panel: 1.5mm Laminate: 1.5mm

Frame: 10% off profile 1.5mm

Related Products

Product Message